ArcelorMittal → Applications → Études de cas – en ligne → Luxembourg | Widening of the railway tracks at the ‘Belval – Mill’ train station (2008)

Luxembourg | Widening of the railway tracks at the ‘Belval – Mill’ train station (2008)

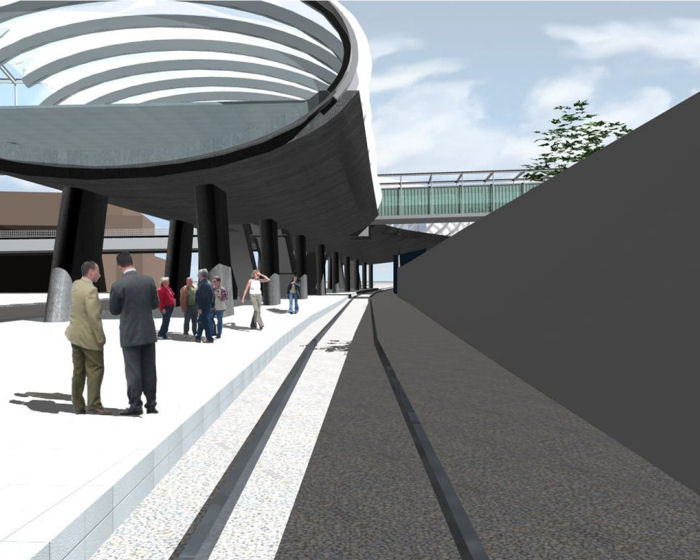

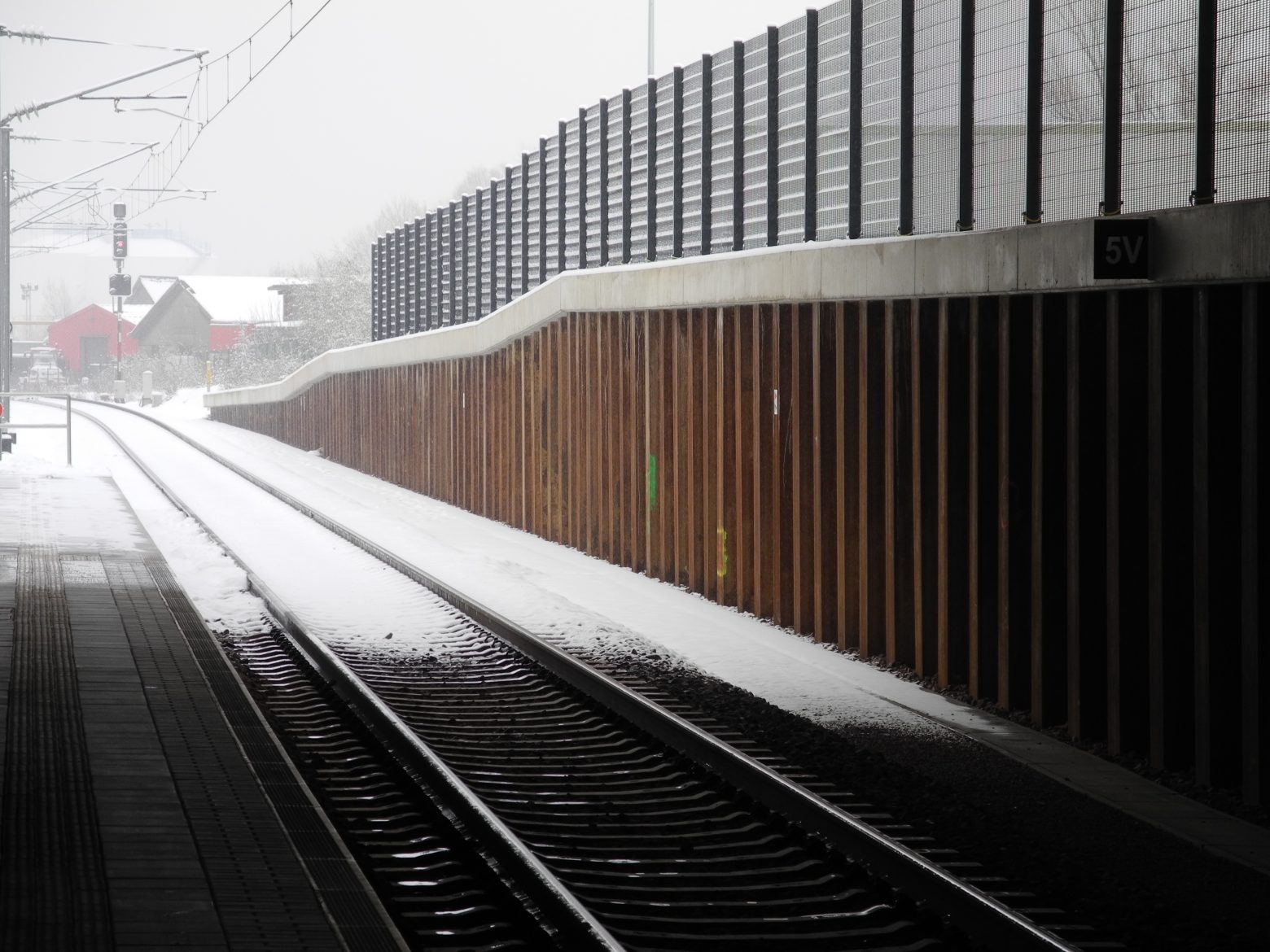

The luxemburgish railway company CFL rehabilitated the train station at ‘Belval – Mill’ in Luxembourg (2008-2009). Steel sheet piles have once again been chosen as a retaining wall for the new quay structure. Indeed, a new cantilever retaining wall has been installed in a few weeks time just a couple of meters behind the old structure that was built early in the 1980’s.

Though the soil borings showed the presence of compact marl at shallow depth, the installation works progressed in a timely manner without any difficulties. This is the result of a judicious choice of the combination sheet pile section and driving method:

Though the soil borings showed the presence of compact marl at shallow depth, the installation works progressed in a timely manner without any difficulties. This is the result of a judicious choice of the combination sheet pile section and driving method:

- the pre-drilling of a hole, followed by a granular fill, loosened the soil at the location of the sheet pile wall,

- in order to guarantee a good driving speed, the choice of the sheet pile section was paramount. In collaboration with ArcelorMittal Commercial RPS’s technical department, the design engineer opted for the PU 18-1.0. Its high stiffness allowed it to be driven with a vibratory hammer at least 1 m deeper than the pre-drilling, which guarantees sufficient embedment of the toe of the pile, and minimizes the deflections of the retaining wall,

- the existing sheet piles stayed in place for quite a long time, but they could be extracted with the same vibrohammer even though the soil consists of cohesive material. Their excellent state of preservation will allow the contractor to reuse them as temporary retaining elements in future projects.

|

Owner |

Ministère des Transports, Société Nationale des Chemins de Fer Luxembourgeois (CFL) | LU |

|

Project manager |

Milestone Consulting Engineers S.à r.l. | LU |

|

Architect |

Atelier d’Architecture et de design Jim Clemens | LU |

|

Subcontractor driving |

Baatz Constructions S.à r.l. | LU |

|

Steel sheet piles |

PU 18-1.0 | S 355 GP | 3.10 - 9.25 m |

|

Quantity |

331 t |

First publication: 2009

Last revision: 01/2019

Dernière modification : février 13, 2019

English

English Deutsch

Deutsch Italiano

Italiano