L'acier durable - EcoSheetPile™ Plus

Des solutions durables pour réduire l’impact environnemental de vos projets

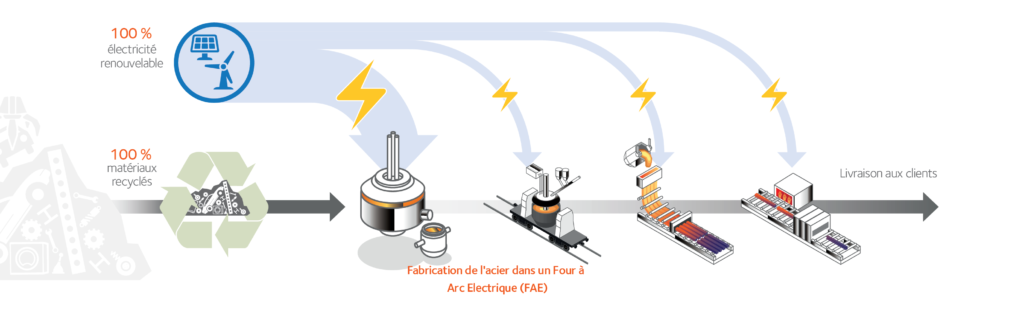

La décarbonation de son activité est l'aspect le plus important de la stratégie à long terme d'ArcelorMittal. Nous nous alignons sur les objectifs de l'Accord de Paris et du «Green Deal» européen. En 2021, nous nous sommes engagés à réduire nos émissions de CO2 en Europe de 35 % d'ici 2030 et à atteindre la neutralité carbone d'ici 2050. Notre nouvelle marque, XCarb®, réunira à terme tous les produits et toutes les activités sidérurgiques d'ArcelorMittal à faibles émissions de carbone ou neutres en carbone.Depuis longtemps, les palplanches acier EcoSheetPile™ sont fabriquées exclusivement par la filière du Four à Arc Électrique (FAE) et leur production n'émet que peu de CO2 par rapport à la valeur moyenne des émissions de CO2 de l'industrie sidérurgique mondiale pour le mode de production conventionnel qui est d'environ 2,3 tonnes de CO2 par tonne d’acier. La Déclaration Environnementale de Produit (DEP) de la gamme de produits EcoSheetPile™, est basée sur une analyse du cycle de vie (ACV) des produits fabriqués par la filière FAE utilisant 100 % de matériaux recyclés. Elle est disponible sur demande.

La nouvelle marque EcoSheetPile™ Plus, intégrée à l’initiative XCarb® de sources recyclées et renouvelables, est basée sur la filière FAE utilisant 100% de matériaux recyclés et utilise en outre 100 % d’électricité renouvelable provenant du même réseau électrique. Cela permet de produire la nouvelle gamme EcoSheetPile™ Plus avec une empreinte carbone réduite par rapport à la production avec le bouquet énergétique habituel, et bien plus si on la compare à la sidérurgie conventionnelle qui émet 2,3 tonnes de CO2 par tonne d’acier*. Certifiée par une déclaration environnementale de produit (DEP) spécifique, la production de la gamme EcoSheetPiles™ Plus n'émet que 409 kg d'équivalent CO2 par tonne d'acier produite. Elle bénéficie également d’une «garantie d’origine» certifiant les sources renouvelables de l'électricité, vérifiée par un auditeur externe.

L'un des principaux avantages des palplanches acier est leur contribution à l'économie circulaire, qui en font un des matériaux de construction les plus durables. En effet, les palplanches acier d'ArcelorMittal peuvent être réutilisées jusqu'à dix fois avant d’être intégralement recyclées dans le processus de fabrication de l’acier par la voie du four à arc électrique. En outre, il est possible d’optimiser davantage l'empreinte carbone des projets de construction à l'aide de solutions sur mesure, reposant sur nos palplanches à haute performance, associées à nos grades d’acier à haute résistance.

Des études indépendantes sur des projets d’infrastructures montrent que des solutions innovantes à base de palplanches EcoSheetPile™ peuvent avoir l'impact environnemental le plus faible par rapport à d'autres solutions techniques. Une ACV complète pour un projet de parking souterrain montre un impressionnant écart de 88 % des émissions de gaz à effet de serre en faveur de la solution EcoSheetPile™ par rapport à son alternative la plus proche dans un matériau différent**. Et la nouvelle gamme EcoSheetPile™ Plus apporte même de meilleurs résultats.

Les palplanches acier d'ArcelorMittal sont un produit de construction respectueux de l'environnement. Comme d'autres produits sidérurgiques européens, elles sont fabriquées dans des usines qui communiquent sur leurs performances environnementales à l'aide d’indicateurs transparents, qui disposent de systèmes de gestion de la qualité certifiés et qui protègent leur personnel par des politiques de santé et de sécurité étendues.

L'impact environnemental des palplanches en acier laminées à chaud d'ArcelorMittal est documenté dans des Déclarations Environnementales de Produit (DEP), enregistrée auprès de EPD International en Suède. Retrouvez plus de détails sur nos DEP sur nos pages dédiées.

* https://www.sustainablefinance.hsbc.com/-/media/gbm/sustainable/attachments/4016-hsbc-csf-steel-report-2019v5.pdf

* https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#

* https://www.worldsteel.org/en/dam/jcr:7ec64bc1-c51c-439b-84b8-94496686b8c6/Position_paper_climate_2020_vfinal.pdf

** Les rapports d'études, élaborés conjointement avec des partenaires externes et nos équipes de R&D, sont disponibles sur demande.

Dernière modification : mars 20, 2024

English

English Deutsch

Deutsch Italiano

Italiano