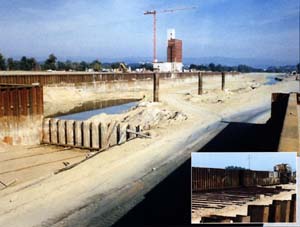

Quay wall | Inland port of Straubing | DE

The port of Straubing to the south of Munich will complete the existing infrastructure on the Rhine-Main-Danube canal. The main dock, built with steel sheet piling, has a maximum depth of 9.80 metres and offers a total quay length of 1 050 metres. Installing the 4 500 tonnes of sheet piles in soil with very difficult geotechnical characteristics required a specific piling procedure to be designed in advance of the main scheme.

This procedure was developed from comparative driving tests carried out in the local tertiary soil that comprises extremely dense silty sand and very hard clays. It took 60 minutes to drive piles to a depth of 18 to 20 metres using a conventional percussion hammer (Delmag D 30) but only 13 to 18 minutes were required using a high frequency vibrator with water-jet assistance.

The obvious cost savings obtained from the use of this technique, together with the reduced vibratory nuisance which it achieves, led to the specification of "vibro-jetting" in the method statement as follow:

"The sheet piles shall be installed by means of a variable frequency vibrator with an adjustable eccentric moment capable of generating a minimum centrifugal force of 3 000 kN. The jetting system to consist of 4 jets of 3/4" diameter welded to each pair of sheet piles. Each jet to be supplied from its own pump delivering a minimum flow of 8 l/s at a pressure of 20 bars.

The following data shall be recorded during driving:

This procedure was developed from comparative driving tests carried out in the local tertiary soil that comprises extremely dense silty sand and very hard clays. It took 60 minutes to drive piles to a depth of 18 to 20 metres using a conventional percussion hammer (Delmag D 30) but only 13 to 18 minutes were required using a high frequency vibrator with water-jet assistance.

The obvious cost savings obtained from the use of this technique, together with the reduced vibratory nuisance which it achieves, led to the specification of "vibro-jetting" in the method statement as follow:

"The sheet piles shall be installed by means of a variable frequency vibrator with an adjustable eccentric moment capable of generating a minimum centrifugal force of 3 000 kN. The jetting system to consist of 4 jets of 3/4" diameter welded to each pair of sheet piles. Each jet to be supplied from its own pump delivering a minimum flow of 8 l/s at a pressure of 20 bars.

The following data shall be recorded during driving:

- penetration depth,

- driving time,

- frequency,

- penetration rate,

- oil pressure,

- jetting pressure."

|

Project owner |

Zweckverband Industriegebiet | DE |

|

Consulting engineer |

Ingenieurbüro Sehlhoff | Straubing | DE |

|

Contractors |

Bilfinger + Berger, Passau Meister | Deggendorf | DE |

|

Steel sheet piles |

L 4S, L 3S (PU 20) | St Sp S |

|

Quantity |

4 500 t |

First published:

Latest revision: 01/2019

Dernière modification : janvier 10, 2019

English

English Deutsch

Deutsch Italiano

Italiano