U jagged walls

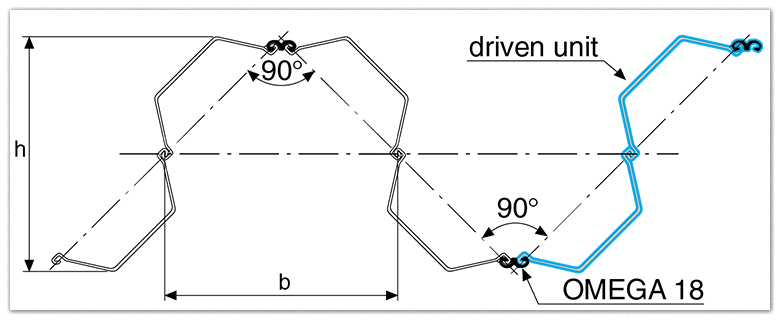

A specific arrangement of U-type steel sheet piles forms a jagged wall. It offers an alternative to a combined wall system where high moment of inertia and section modulus are required.

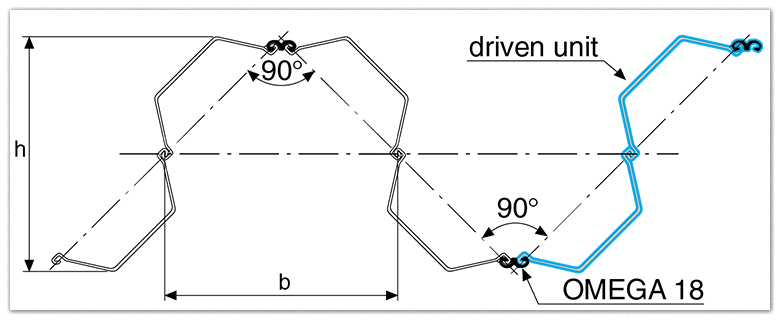

U Jagged Wall with Omega 18 connector

U Jagged Wall with Omega 18 connector

The geometrical values shown in the table assume an efficient solidarisation of each driving element, i.e. crimping or (partial) welding of the common interlock of a double pile. The OMEGA 18 corner section is threaded and welded at the mill, either by tack welding, in which case it does not contribute to the section properties of the jagged wall, or by an appropriately designed weld, so that it fully contributes to the section properties.

Note that for supported walls, either with an anchorage or with a strut system, an adequately designed stiffening system (plates, concrete capping beam,...) must be provided at the support levels.

Due to the geometry of the wall, a special guiding frame, which shall be stiff enough, is required for the installation.

The geometrical values shown in the table assume an efficient solidarisation of each driving element, i.e. crimping or (partial) welding of the common interlock of a double pile. The OMEGA 18 corner section is threaded and welded at the mill, either by tack welding, in which case it does not contribute to the section properties of the jagged wall, or by an appropriately designed weld, so that it fully contributes to the section properties.

Note that for supported walls, either with an anchorage or with a strut system, an adequately designed stiffening system (plates, concrete capping beam,...) must be provided at the support levels.

Due to the geometry of the wall, a special guiding frame, which shall be stiff enough, is required for the installation.

Dernière modification : novembre 11, 2024

U Jagged wall

–

| Section | b | h | G | Iy 1) | Wel,y 1) | Sy | |||||||||||||

| without Omega 18 | with Omega 18 | without Omega 18 | with Omega 18 | without Omega 18 | with Omega 18 | ||||||||||||||

| mm | mm | kg/m2 | cm4/m | cm4/m | cm3/m | cm3/m | cm3/m | cm3/m | |||||||||||

| AU 14 | 1 135 | 1 115 | 153,2 | 275 920 | 334 450 | 5 080 | 5 995 | 3 080 | 3 625 | ||||||||||

| AU 16 | 1 135 | 1 115 | 167,9 | 307 090 | 365 630 | 5 650 | 6 555 | 3 435 | 3 980 | ||||||||||

| AU 18 | 1 135 | 1 136 | 171,9 | 329 420 | 387 960 | 5 800 | 6 830 | 3 595 | 4 135 | ||||||||||

| AU 20 | 1 135 | 1 139 | 186,6 | 362 620 | 421 160 | 6 370 | 7 400 | 3 960 | 4 505 | ||||||||||

| AU 23 | 1 135 | 1 171 | 195,8 | 390 770 | 449 300 | 6 675 | 7 675 | 4 235 | 4 780 | ||||||||||

| AU 25 | 1 135 | 1 173 | 210,4 | 424 630 | 483 170 | 7 240 | 8 240 | 4 610 | 5 150 | ||||||||||

| PU 12 | 923 | 903 | 162,8 | 188 980 | 235 400 | 4 275 | 5 210 | 2 590 | 3 125 | ||||||||||

| PU 12S | 923 | 903 | 174,0 | 202 370 | 248 810 | 4 570 | 5 510 | 2 770 | 3 305 | ||||||||||

| PU 18 | 923 | 955 | 186,2 | 244 470 | 290 890 | 5 120 | 6 095 | 3 215 | 3 755 | ||||||||||

| PU 22 | 923 | 993 | 206,3 | 286 030 | 332 460 | 5 760 | 6 695 | 3 690 | 4 230 | ||||||||||

| PU 28 | 923 | 1 027 | 240,3 | 349 890 | 396 310 | 6 810 | 7 715 | 4 465 | 5 000 | ||||||||||

| PU 32 | 923 | 1 011 | 267,0 | 389 310 | 435 740 | 7 705 | 8 625 | 5 015 | 5 550 | ||||||||||

| GU 11N | 923 | 903 | 150,0 | 167 340 | 213 770 | 3 790 | 4 735 | 2 335 | 2 875 | ||||||||||

| GU 14N | 923 | 920 | 158,8 | 198 710 | 245 140 | 4 320 | 5 330 | 2 645 | 3 180 | ||||||||||

| GU 18N | 923 | 955 | 186,2 | 244 470 | 290 890 | 5 120 | 6 095 | 3 215 | 3 755 | ||||||||||

| GU 22N | 923 | 993 | 206,3 | 286 030 | 332 460 | 5 760 | 6 695 | 3 690 | 4 230 | ||||||||||

| GU 28N | 923 | 1 027 | 240,3 | 349 890 | 396 310 | 6 810 | 7 715 | 4 465 | 5 000 | ||||||||||

| GU 32N | 923 | 1 011 | 267,0 | 389 310 | 435 740 | 7 705 | 8 625 | 5 015 | 5 550 | ||||||||||

| b | Width of a system |

| h | Height of the wall |

| G | Mass |

| Iy | Moment of inertia |

| Wel,y | Elastic section modulus |

| Sy | Static moment |

| 1) | Assumption: correct shear force transfer across the interlocks on the neutral axis |

English

English Deutsch

Deutsch Italiano

Italiano